TFDR-3

Flow Improver & Drag Reducer for Crude Oil

Elite Performance

- Greater than 80% drag reduction with freeze protection in a more environmentally friendly formula

- Suitable for operation in temperatures down to 14 def F (-10 deg C)

- Increases flow rates while maintaining current pipeline pressures

- Maintains flow while reducing pipeline pressures

- Allows shutting down of intermediate pumping stations

Superior Technology

- Improves pipeline capacity without capital investment

- Less polymer required to achieve a given performance

- Lower injection rates than other drag reducers

- Faster dissolution rates than other drag reducers

- Reduces crude heat loss

Provides the answer to crude petroleum pipeline needs

TFDR-3 Advanced Flow Improver and Drag Reducer is a part of TFA’s portfolio of innovative and technologically superior flow improver solutions. This pioneering suspension product provides the answer to crude petroleum pipeline needs in environmentally sensitive, cold weather environments, as well as applications with topographical or logistical challenges requiring higher energy for throughput.

Characteristics

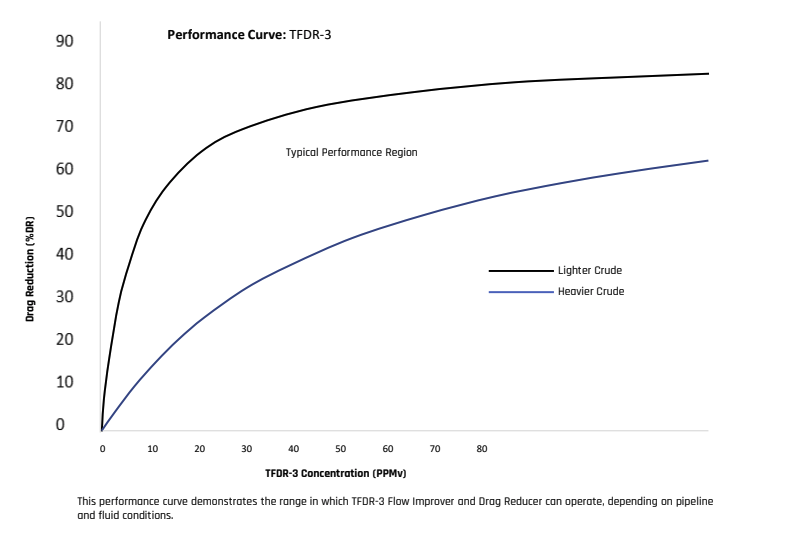

TFDR-3 exhibits a dose response drag reduction performance equivalent to products that facilitate a warm to cold weather flow improver product transition. TFDR-3 is an aqueous suspension product with freeze protection, suitable for operation in temperatures down to 14 deg F (- 10 deg C).

Developed with eco-toxicity concerns in mind, TFDR-3 delivers high drag reduction in crude oil applications both onshore and offshore, while exhibiting low aquatic toxicity.

TFDR-3 can provide greater than 80% drag reduction. This benefit allows companies to strategically reduce pipeline operating costs, increase throughput, decrease pressure or shut down intermediate pump stations.

TFDR-3 dissolves into flowing product without coating pipeline walls.

The polymer technology utilized by TFA allows greater amounts of active polymer to be deployed in a fixed amount of product while improving the dissolution dynamics.

The polymer of choice shows excellent hydrocarbon affinity and is able to attain elevated levels of drag reduction under varied operating scenarios. It also has the strength to effectively endure shear forces.

Handling

TFDR-3 is easy to handle, store and clean up. It flows easily and does not require nitrogen pressurized storage tanks.

General

Application: Light and medium petroleum crude oil

Flow Improver Type: Suspension

Carrier: Water

Performance

Maximum Drag Reduction: Greater than 80%

Typical Concentration: 5 to 50 ppm

Typical Properties

Color: White

Density: 8.2 lbs/gal (0.99 g/cm3)

Flash Point: Not applicable

Viscosity: 160 cP @ 511s-1 (Non-Newtonian) at 77 deg F / 25 deg C

Freezing Point: 14 deg F (-10 deg C)

Boiling Point: 221 deg F (105 deg C)

Vapor Pressure: 0.46 psia (23.9 mm H) @ 77 deg F / 25 deg C

Handling

Operating Range: 14 deg F to 120 deg F (-10 deg C to 48.9 deg C)

Product Stability: Stable suspension

Pressure Heating: Intermittent agitation recommended

Injection Equipment

Pumps: Various designs available for different injection range and environments

Range: 5 to 2,500 gal/day (20 to 9,500 L/day)

Flowmeter: Mass (Coriolis)

Automation: Available

Safety and Environmental

Safety and Health (per U.S. OSHA): Nonflammable. Expected to be a low hazard for usual industrial handling by trained personnel.

Environmental (per U.S. EPA): Not classified as hazardous waste